Discover how to make a paracord watch band in this instructional video presented by Rock Paracord. Enjoy your own custom watchband by learning how to make a paracord watch band.

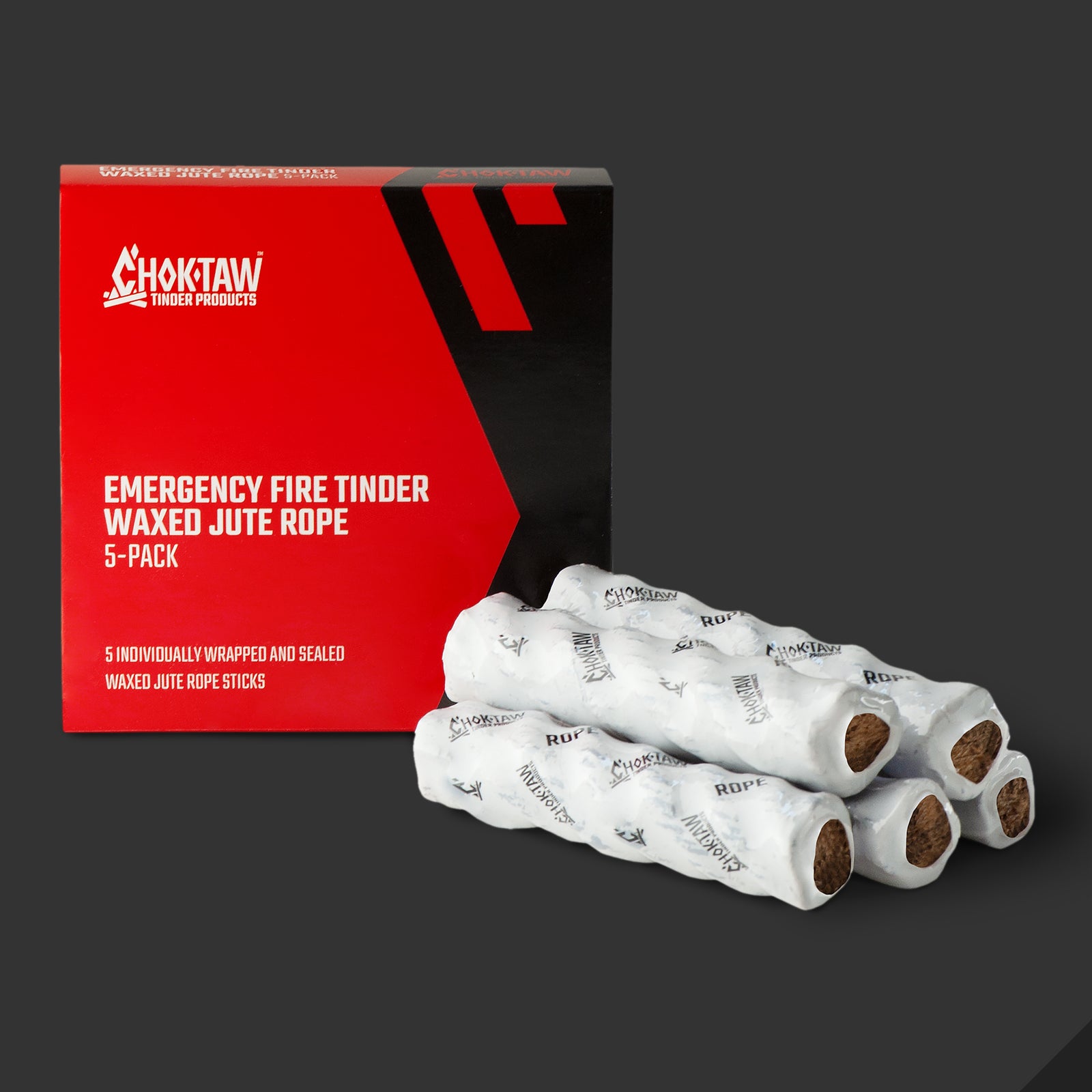

You will need a watch face, a 5/8” side buckle, forceps, scissors, a paracord needle, a lighter, and 5’ of either SurvivorCord or WarriorCord, along with four separate sections of gutted paracord that are about 1’ in length. Melt the ends of the paracord to keep them from fraying while you are working with them.

Fold the 5’ length of paracord over so that one side has 2’ and the other side has 3’. Take one of the side buckle ends and attach the paracord using a cow hitch. Put the free ends of the paracord through the other buckle end. Make sure the paracord is fed through in the correct direction, otherwise it will twist. Bring the buckle ends together until they are about the length of your wrist apart. This will create the backbone of the watchband and determines its size.

Take the ends of the paracord and wrap it through the buckle end a second time and then back through the other end of the plastic buckle. Each paracord end should go on its respective side of the cow hitch. You should now have four lines running between the buckle ends, with two free ends.

Cut the excess off the right cord, leaving an inch or two. Fuse the remaining to the cord directly next to it. This will be worked into the weave, so you won’t be able to see it. You will be doing all of the weaving with the remaining left free end.

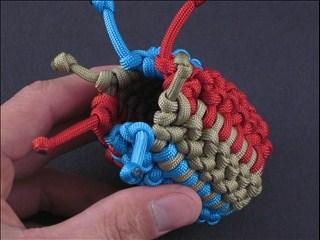

The weave is simple, just take the end and work it over the first cord, under the two middle cords, and over the last cord, and then pulling tight. When you come back around, work under the outer cords, and over the two inner cords. Tighten each weave and push up towards the buckle. Don’t make it to tight otherwise the weave will begin to twist.

Repeat this process until you have reached the other buckle and worked as many weaves as possible between the two buckles. With your last weave you want to make sure that the remaining paracord is coming out towards the back of the watchband. Weave the remaining end through a few of the existing weaves and then cut the excess and melt the end into the weave.

The next thing to do is weave the watch face onto the watchband. To start you will want to create a space on between the 12th and 13th weave from the top. Put the four gutted strands of paracord through the loop on the watch face so there is an equal amount facing up and down. Place the watch face with the looped part at the opening on the watchband.

Weave the top strands into the backside of the bracelet, working towards the top of the watchband. The four bottom cords should be weaved into six or seven of the existing weaves and up through the other loop on the watch face.

This is the most time consuming part because you have to weave eight separate ends into the back of the watchband. Once you are done weaving the watch face onto the watchband, cut the remaining ends and melt them into the weave. That’s it, you just made you own customized paracord watchband.